A perfect product comes only from the utmost precision, in every stage of work

The peculiarity of our production cycle is that it is entirely followed by our company, in each phase.

The direct management of the planning and execution allows us to create brass components of any kind, unreleased and differentiated according to demand. Furthermore, we guarantee absolute quality in the choice of materials and in manufacturing methods.

The internal total management of the supply chain allows Pintossi+C to grant a capillary control of each step and an ultimate production flexibility.

All the supply chain, from hot brass forging up to the stocking department in the dedicated logistic site in Gussago, is entirily carried out and managed by the company intself, complying with the highest internal and regulatory quality standards.

Using the most advanced controls and tests methods for the produced componets during the different manufacturing steps and the applications of the industry 4.0 concepts, allowed to take advantage of the ultimate technological innovations, granting an excellent quality and improving the production efficiency.

01

Raw material receiving

Receiving brass in extruded bars for hot forging and in drawn bars for turning operations represents the first step towards the creation of the finished product. Pintossi+C suppliers are all located nearby. The firsts quality controls take place during this phase to verify compliance with internal requirements.

02

Hot brass forging

The department is equipped with high efficiency automatic brass hot forging presses, with capacity up to 550 tons, making it possible to press brass components as big as 4”.

03

Sandblast department

The surface treatment of forged brass parts is performed by a high efficiency sand blast machine, which removes possible surface impurities originating from the hot forging process. The final result is a clean and smooth surface free of defects.

04

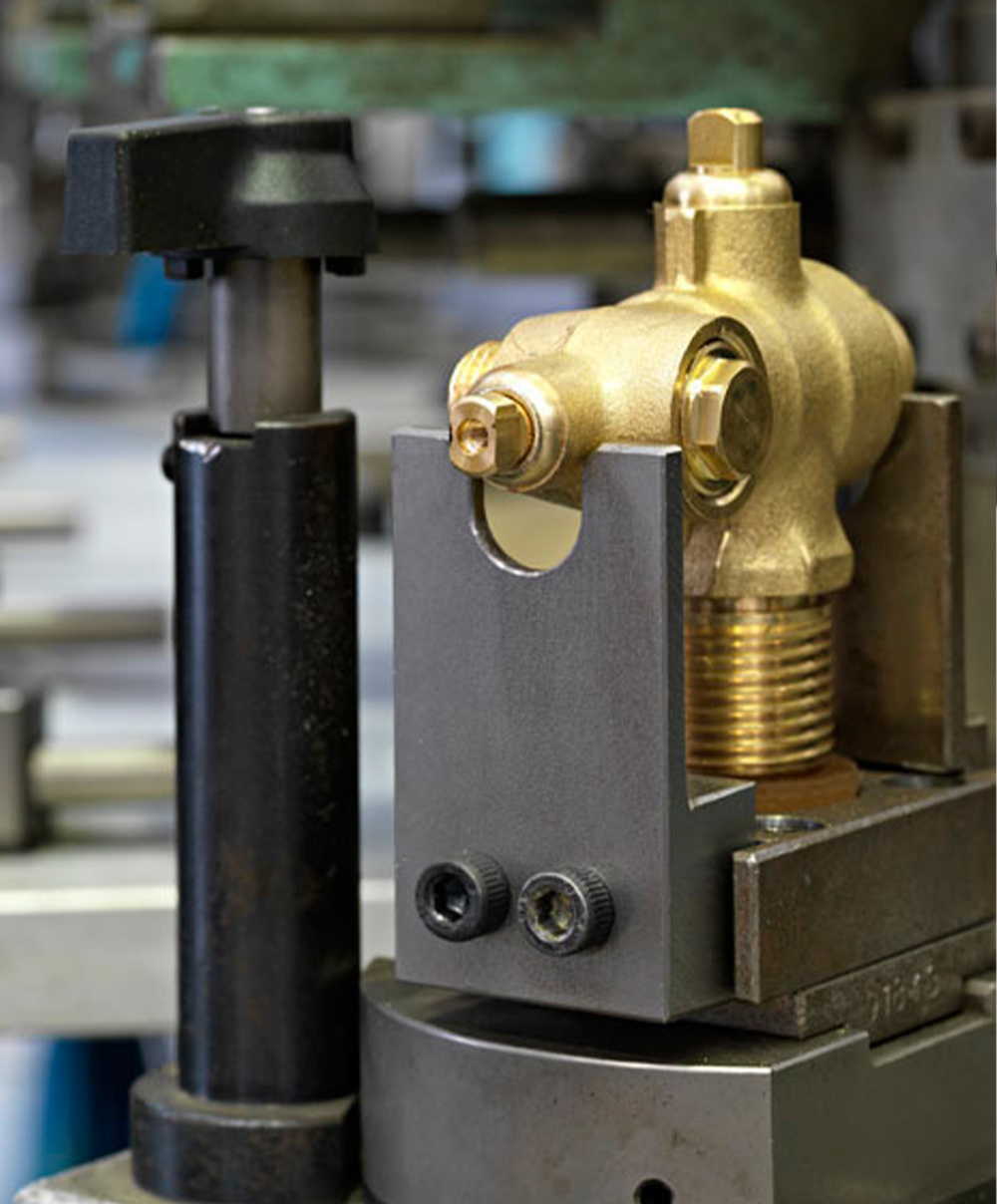

Transfer department

Equipped with vertical and horizontal axis rotary table transfer machines, with CNC units and working stations. Robots for automatic loading and unloading of brass parts in or from the machines, with integrated machine vision systems, complete this department.

05

Assembling

This department is equipped with automatic and semi-automatic machines for assembling, testing and packaging many products like radiator valves, air vents, safety valves, etc.; manual assembly areas for the assembly of integrated systems and various components; a test bench for the pressure testing of relief valves, to control the correct opening and closing within the set pressure range; a test room for thermostatic actuators, complying with the requirements of the EN215 Standard.

06

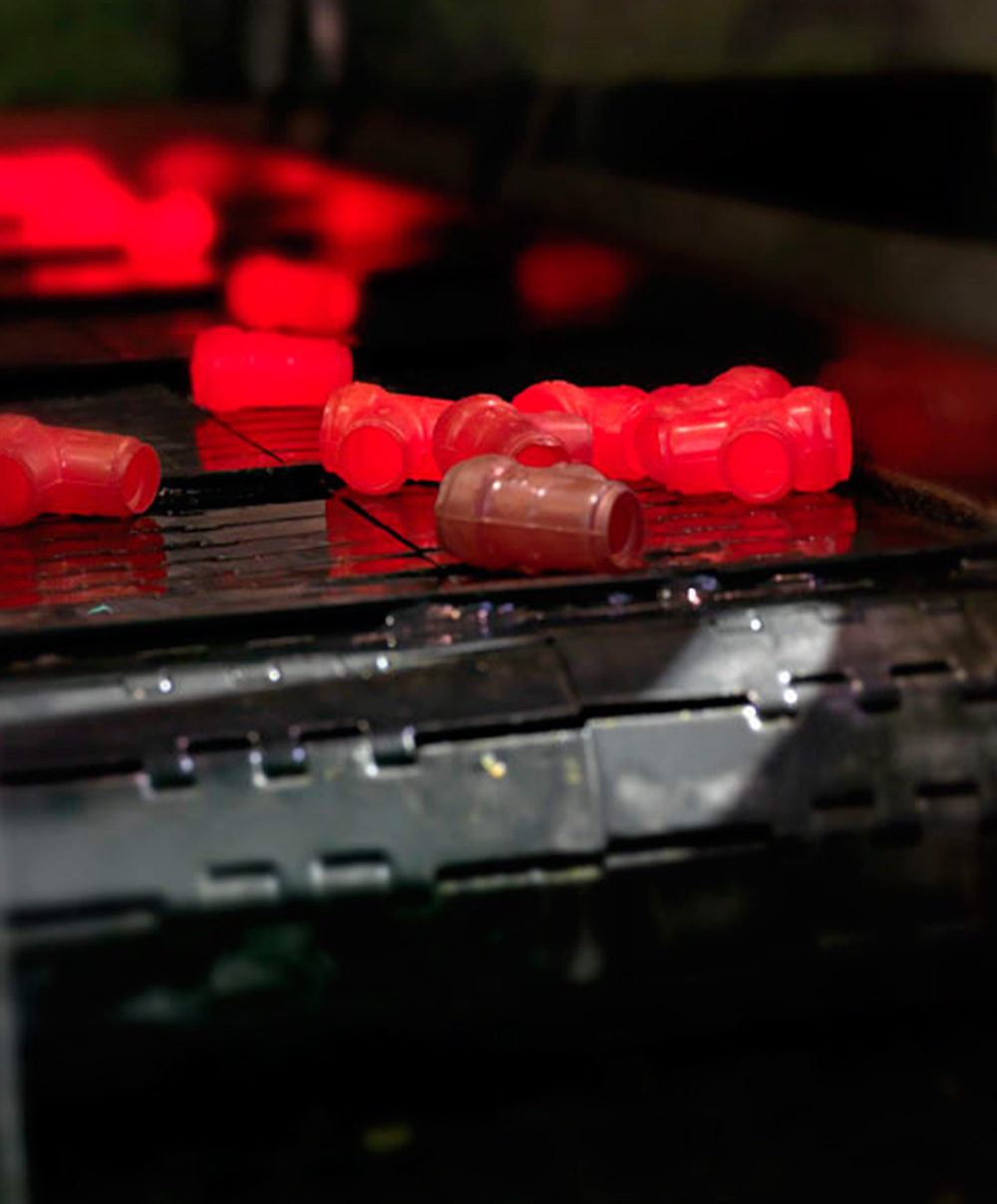

Packaging

In order to ensure an excellent quality of our products over time and in order to avoid possible dents, the packaging operations are carried out with the utmost care and respecting the rigorous indications set by the internal Quality procedures, in terms of goods handling and of respect for load management.

The final packaging is carried out with the aid of a fully automatic packaging line.

07

Storage

The finished product warehouse is located in Gussago, in the immediate proximity of the main roads in order to allow an easy shipment of orders. The large covered warehouse covers an area of over 3.000 sqm.

Pintossi+C is a strong company, that over the years has matured and renewed itself in order to offer to its customers an accurate and professional service, by offering only safe and certified products.

The company quality system is certified according to UNI EN ISO 9001: 2015 since 1997. For Pintossi+C this certification does not represent just an acronym, but a way of working and doing business which takes inspiration by very specific principles. The company has recently renewed this certification in 2020, following the new updated requirements and standards.

With the purpose to increase the performance and reliability of its products more and more, the company cooperates with the most important italian and european bodies and laboratories, other than having achieved important awards and certifications on the different items which identify Pintossi+C core business.