Pintossi+C magnetic dirt separator range

PINTOSSI MAGNETIC DIRT SEPARATORS – PROTECTION, EFFICIENCY AND REGULATORY COMPLIANCE

The role of the dirt separator in heating systems

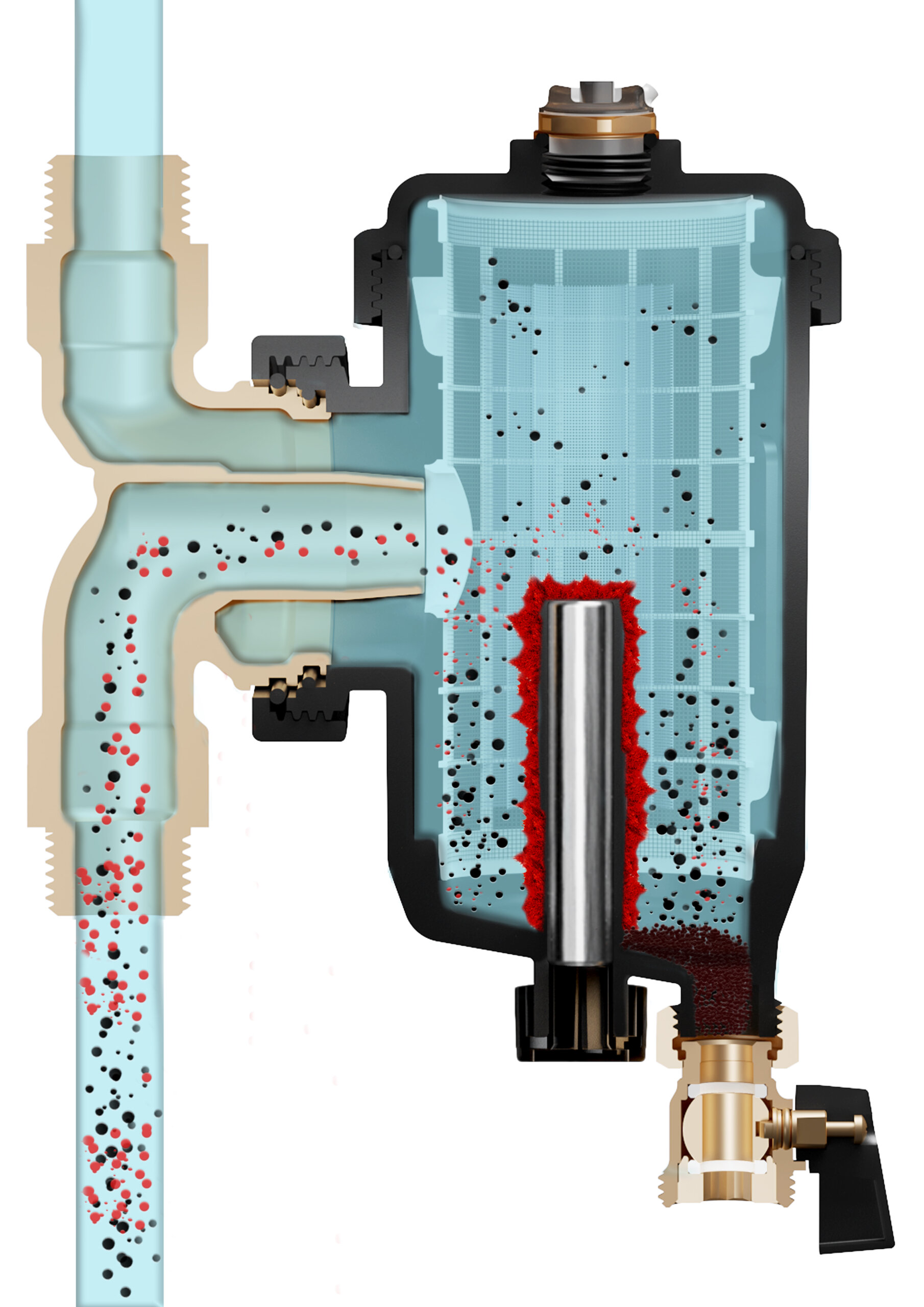

In heating or air-conditioning systems, the circulating water may contain impurities such as ferrous particles (iron oxides) generated by corrosion of metallic materials, as well as non-ferrous particles resulting from chemical processes or sludge deposition. If allowed to circulate freely within the system, these impurities may cause blockages, component wear (circulators, heat exchangers, valves), reduced energy efficiency and system malfunctions.

Magnetic dirt separators combine mechanical filtration with a special magnetic separation, providing an effective system for plant protection:

- they retain ferrous impurities through high-intensity magnets;

- they intercept solid non-ferrous particles by means of filter meshes;

- they facilitate system maintenance and periodic cleaning;

- they extend the service life of boilers and heat pumps;

- they ensure system efficiency;

- they help maintain system design parameters and reduce failures.

From a regulatory point of view, in accordance with general industry recommendations such as UNI 8065:2019 for heating systems, it is considered good practice to install water treatment systems (including filtration and dirt separation) in order to reduce corrosion and scaling phenomena and to maintain optimal operating conditions over time.

THE RANGE OF MAGNETIC DIRT SEPARATORS

- Magnetic filters for boilers

Magnetic filters for boilers are characterised by extremely compact dimensions, making them ideal for installations in confined spaces.

The specific design of Pintossi dirt separators nevertheless ensures high performance, both in terms of filtration efficiency and guaranteed minimum flow rates, without compromising correct system operation.

The combination of these features allows effective removal of impurities from the circuit, helping to extend the service life and maintain the efficiency of the boiler and the entire system.

MINIMAG – The most compact in its category

Minimag is a magnetic dirt separator featuring an extremely compact design, developed for under-boiler installation or confined technical spaces, ensuring continuous protection of the boiler and sensitive system components.

Main features:

- body made of high-resistance technopolymer;

- neodymium magnet rated at 13,200 Gauss with large attraction surface;

- 800-micron stainless steel filter mesh;

- maximum operating pressure: 6 bar;

- maximum operating temperature: 90 °C;

- Kv = 4.46 m³/h;

- suitable for water or glycol solutions up to 30%;

- ball valve, swivel nut and drain plug included.

Minimag is particularly suitable for residential applications and small systems where reduced dimensions are a key requirement, while still providing effective impurity separation.

The presence of valves and fittings with swivel nuts significantly simplifies installation operations, allowing fast and precise installation, especially in under-boiler connections using flexible pipes.

DUOMAG – Compact and versatile

Duomag is a compact yet high-performance magnetic dirt separator, designed to provide advanced protection in civil and residential systems, collecting both ferrous impurities and non-ferrous solid particles.

Main features:

- body made of high-resistance technopolymer;

- neodymium magnet rated at 14,100 Gauss with large attraction surface;

- 800-micron stainless steel filter mesh;

- maximum operating pressure: 6 bar;

- maximum operating temperature: 90 °C;

- Kv = 5.56 m³/h;

- installation in both vertical and horizontal positions;

- suitable for water or glycol solutions up to 30%;

- ball valve, double swivel nut and drain plug included.

Duomag, with its combination of mechanical and magnetic filtration, represents a versatile solution for under-boiler protection in civil and residential installations.

Thanks to installation in both horizontal and vertical positions, it allows easy installation even in confined spaces.

The presence of valves and fittings with swivel nuts further simplifies installation, enabling quick and accurate assembly, especially in under-boiler connections with flexible pipes.

Magnetic filters for thermal plants and heat pumps

Magnetic dirt separators for thermal plants and heat pumps are designed to handle high flow rates and more demanding operating conditions, typical of medium- and large-capacity systems.

The specific design of Pintossi dirt separators ensures a high impurity separation capacity, even in the presence of large water volumes, while guaranteeing excellent hydraulic performance and low pressure losses.

These solutions effectively remove ferrous particles and solid impurities, helping to protect critical components such as circulators and heat exchangers and to maintain long-term energy efficiency and system reliability.

MULTIMAG – Multifunctional

Multimag is designed for systems with higher flow rates and increased protection requirements, such as thermal plants or installations with heat pumps and hybrid systems.

Main features:

- body made of high-resistance technopolymer;

- neodymium magnet rated at 14,000 Gauss with large attraction surface;

- internal reticulated element;

- 300-micron stainless steel filter mesh;

- maximum operating pressure: 4 bar;

- maximum operating temperature: 90 °C;

- Kv = 14.3 m³/h (DN25);

- swivel fitting for installation on vertical or horizontal pipes;

- suitable for water or glycol solutions up to 30%;

- manual air vent usable as a chemical additive injection point;

- drain valve with ¾” connection.

Multimag represents the Pintossi dirt separator with the best balance between performance and efficiency.

The mechanical and magnetic separation process inside the dirt separator is based on the synergistic action of four distinct filtration stages, designed to maximise the retention efficiency of solid and ferrous impurities in the heat transfer fluid:

- First filtration stage: removal of larger particles through an internal stainless steel reticulated element.

- Large-volume decantation chamber (500 ml): significant reduction of fluid velocity, promoting further separation of impurities by gravity.

- High-power magnet rated at 14,000 Gauss: effective capture of ferrous particles.

- Final filtration stage: large-surface 300-micron filter mesh for removal of residual particles.

Routine maintenance and cleaning can be carried out by simply opening the drain valve located at the bottom of the dirt separator.

Optional insulation is available.

Multimag is available with male or female connections or with ball valves, ensuring installation flexibility for different system configurations.

TOTALMAG – Guaranteed flow rates and robustness

Totalmag is a self-cleaning magnetic dirt separator designed for systems with heat pumps, hybrid systems and high-flow-rate circuits, where intensive filtration and efficient impurity collection are required.

Main features:

- body made of CW617N brass;

- neodymium magnet rated at 12,000 Gauss with large attraction surface;

- large 300-micron stainless steel filter mesh;

- maximum operating pressure: 10 bar;

- maximum operating temperature: 110 °C;

- Kv = 17.7 m³/h (DN25);

- suitable for water or glycol solutions up to 30%;

- automatic air vent usable as a chemical additive injection point;

- drain valve with hose connection.

Totalmag is a self-cleaning dirt filter and can be supplied with or without an automatic air vent, making it ideal for installations where reduced manual maintenance and continuous protection are required.

Its design features and extremely low pressure losses make it particularly suitable for systems requiring high flow rates, such as heat pump installations.

Routine maintenance and cleaning can be carried out by simply opening the drain valve located at the bottom of the dirt separator.

Regulatory references and best installation practices

Proper management of the quality of the heat transfer fluid in heating and air-conditioning systems is a fundamental requirement to ensure energy efficiency, reliability and long service life. In this context, the use of magnetic filtration and dirt separation devices is considered part of the best installation practices required by technical standards.

The UNI 8065 standard (Water treatment in civil heating systems) establishes the requirement to adopt suitable water treatment systems in order to limit corrosion, scaling and the accumulation of solid impurities within circuits. Among the recommended solutions are filtration and sludge separation systems, particularly suitable for intercepting ferrous residues generated by corrosion of metallic materials.

Furthermore, regulatory requirements and the guidelines of major boiler and heat pump manufacturers highlight that impurities in system water can compromise the correct operation of heat exchangers, circulators and valves, resulting in performance degradation and increased maintenance costs.

The installation of magnetic dirt separators therefore allows to:

- maintain system design conditions over time;

- reduce the risk of failures and functional blockages;

- facilitate routine maintenance operations;

- contribute to compliance with regulatory requirements and manufacturers’ recommendations.